Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

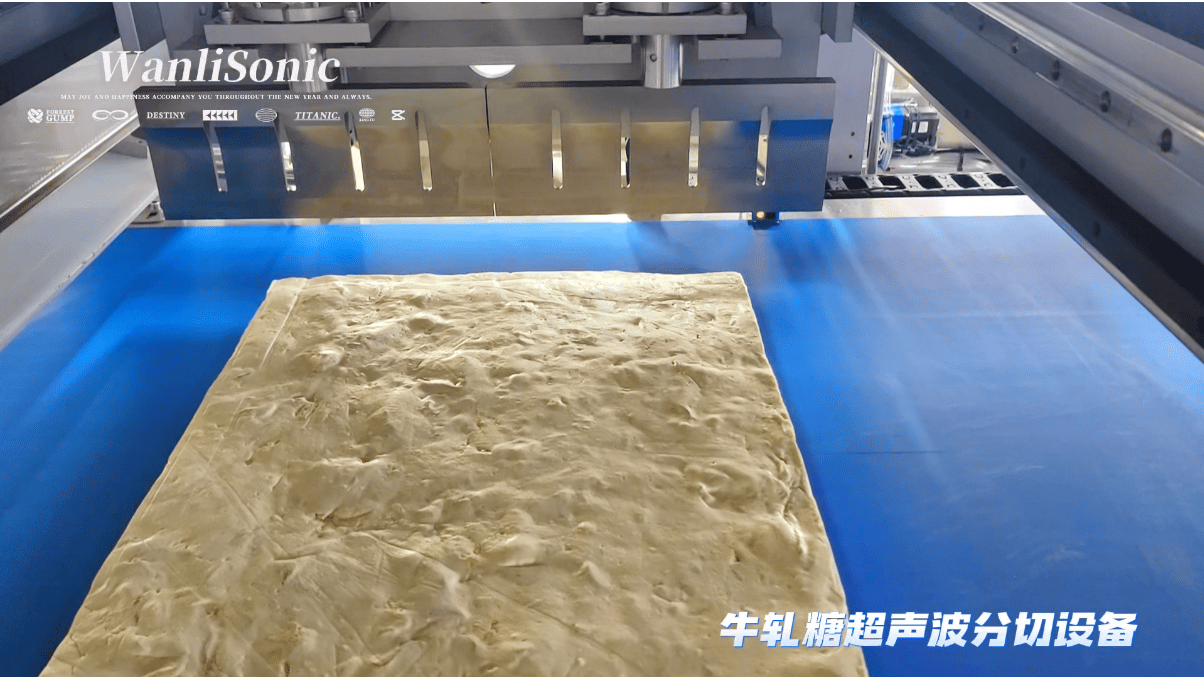

Wanlisp4-300K900L3500 Ultrasonic Nougat Cutting Machine represents a breakthrough in confectionery manufacturing technology. Utilizing advanced 40kHz ultrasonic vibration, this innovative system delivers unparalleled precision cutting for even the stickiest nougat varieties. The Teflon-coated blades and specialized vibration technology completely eliminate product adhesion, reducing waste by up to 30% compared to conventional cutting methods.

★Average speed: 30-40 cuts per minute

★Touch screen with user-friendly interface

★Reliable and durable ultrasonic blade

★Increased quality and labor saving enhance capacity

★Improved portion quality and consistency

Product Details Display

|

|

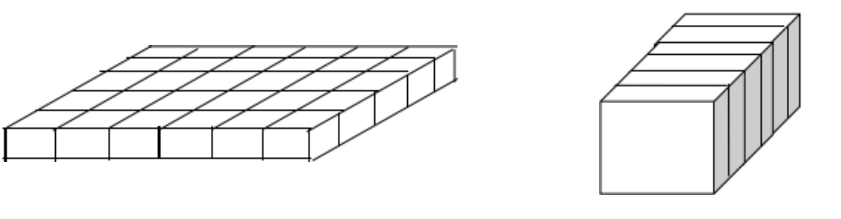

| Cutting Mode & Cutting Example |

|

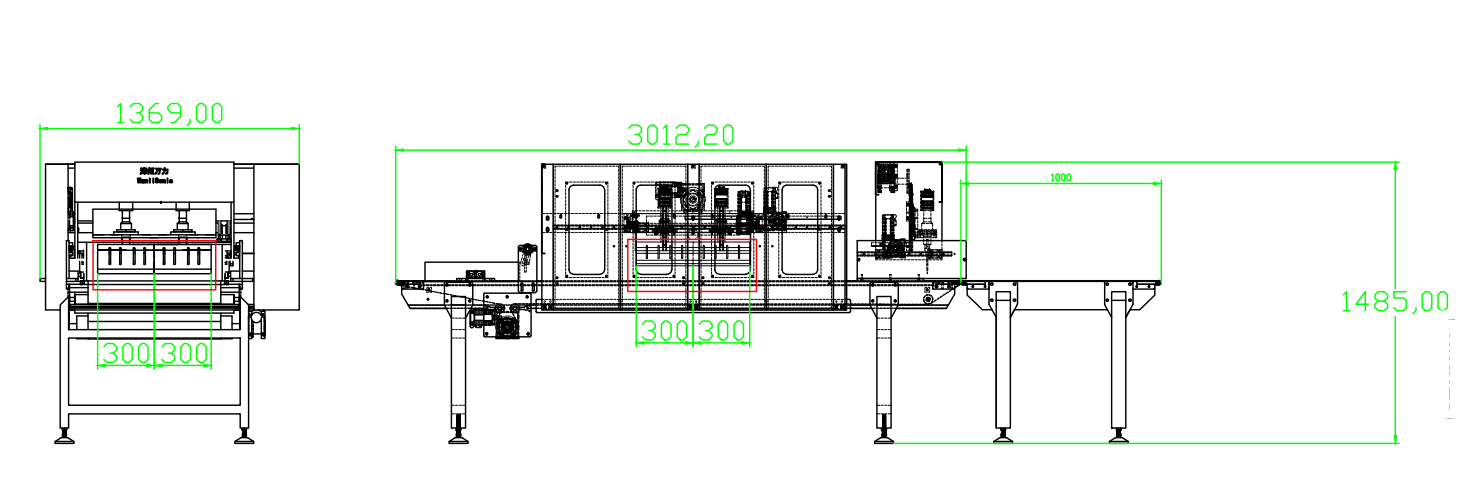

| Features | Machine Dimensions (L xWxH) |

• Fully Stainless steel construction & food grade plastics |

|

Product Description

Model |

Wanlisp4-300K900L3500 |

Dimensions |

L3000*W1400*H1550mm |

Weight |

Net Wt. 550KGS, Gross Wt.600KGS |

Voltage |

220V, single |

Rated power |

8000W |

Frequency |

50Hz-60Hz |

Ultrasonic Frequency |

20000Hz |

Amplitude |

20%-40% |

Cross cutting speed |

20-60cuts/Minute; high-speed model:60-180cuts/Minute |

Slit cutting speed |

30-40cuts/Minute; high-speed model:40-100cuts/Minute |

Number of blades |

4 (optional) |

Blade materials |

Titanium Alloy |

Blade size |

300mm/pc (optional) |

Cut type |

Square, rectangular, slices |

Components

No. |

Name of Component |

Brand |

Introduction |

Picture |

1 |

Ultrasonic Blade |

Wanlisonic |

Made of Titanium Alloy material, The mechanical strength is better than that of steel, the acoustic transmission is good, the sound frequency is not depleted in its internal transmission, and it has strong acid-base corrosion ability, |

|

|

2

|

Ultrasonic Generator

|

Wanlisonic |

The advantages of original ultrasonic generator include automatic frequency lock function, automatic frequency tracking,low coefficient of temperature change, and there will be 7*24 hours of aging test before delivery.

|

|

3 |

Thicken and Bigger Cutting Machine Framework |

Wanlisonic |

Stainless steel, easy to clean, made with thicken china standard material, made by Anshan Iron and Steel Company |

|

4 |

Energy Transducer |

Wanlisonic |

Electric energy is converted to kinetic energy, to make the blade cut the products |

|

5 |

Touch Screen |

Wecon/Delta |

Intelligence control, for the operation and monitor |

|

6 |

PLC Control System |

Wecon/Delta |

Anti-error operation, safety testing, alarm indication |

|

7 |

Reley |

OMRON |

Touch switch |

|

8 |

Sensor |

Leuze |

For Testing whether have the products under the blade |

|

9 |

Frequency Inverter |

SANJING or Delta |

Driving the conveyor to work |

|

10 |

Servo Motor |

Dorna |

Driving the blade to work |

|

11 |

Stepmotor |

Dorna |

Driving the blade to work |

|