Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

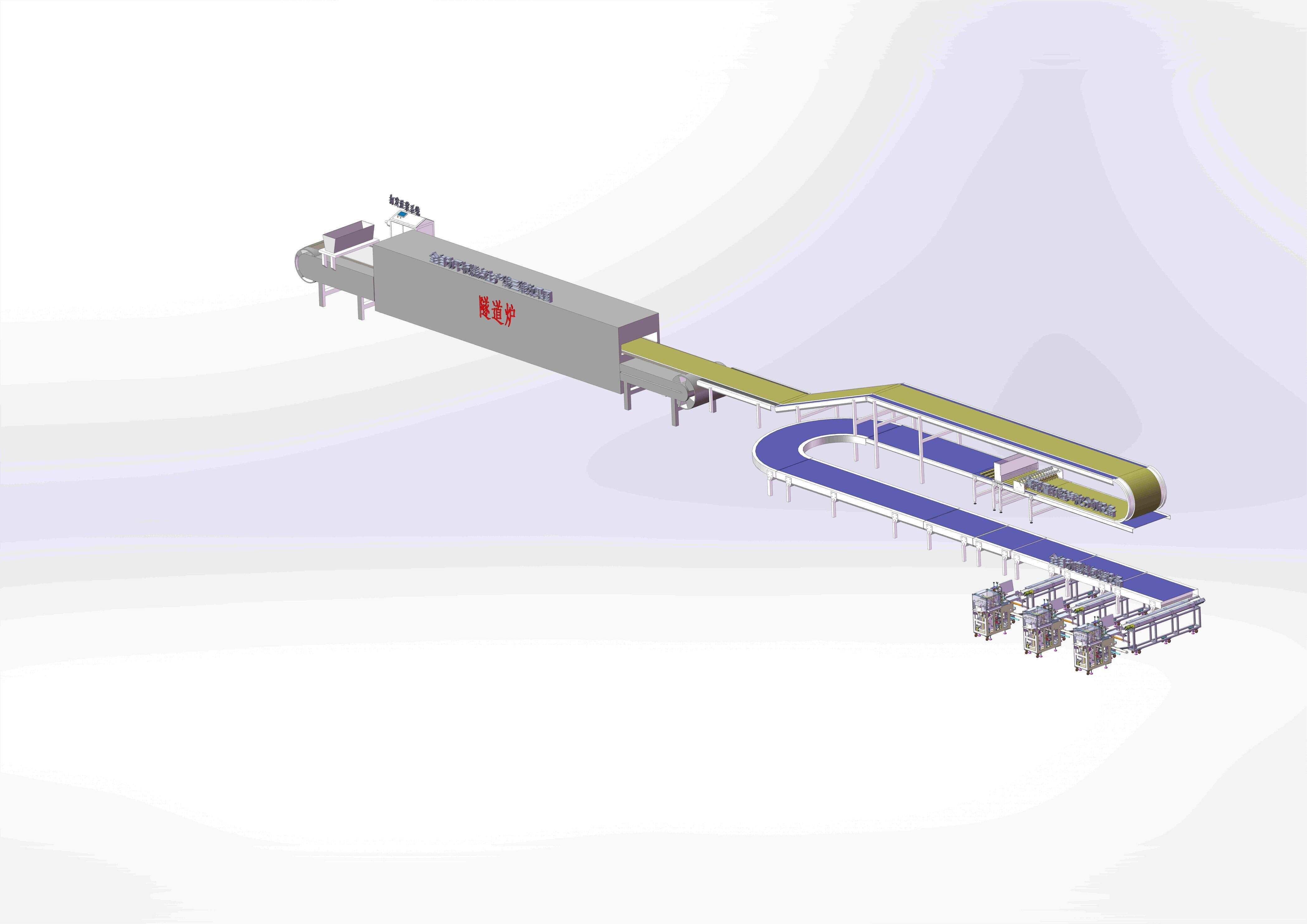

Wanlisp 888 Automatic Cake Production Line is a combination of equipment used to automatically produce cakes, which can efficiently and hygienically complete the entire process from raw material processing to finished product packaging. Its main components include: raw material processing system, batter preparation system, baking system, cooling system, decoration system, packaging system, control system. This production line is widely used in food processing companies, bakery chains, etc. to meet large-scale production needs.

★Efficiency: Automated production greatly improves efficiency.

★Touch screen with user-friendly interface

★Hygiene: Closed operation reduces the risk of contamination.

★Increased quality and labor saving enhance capacity

★Improved portion quality and consistency

Product Details Display

|

|

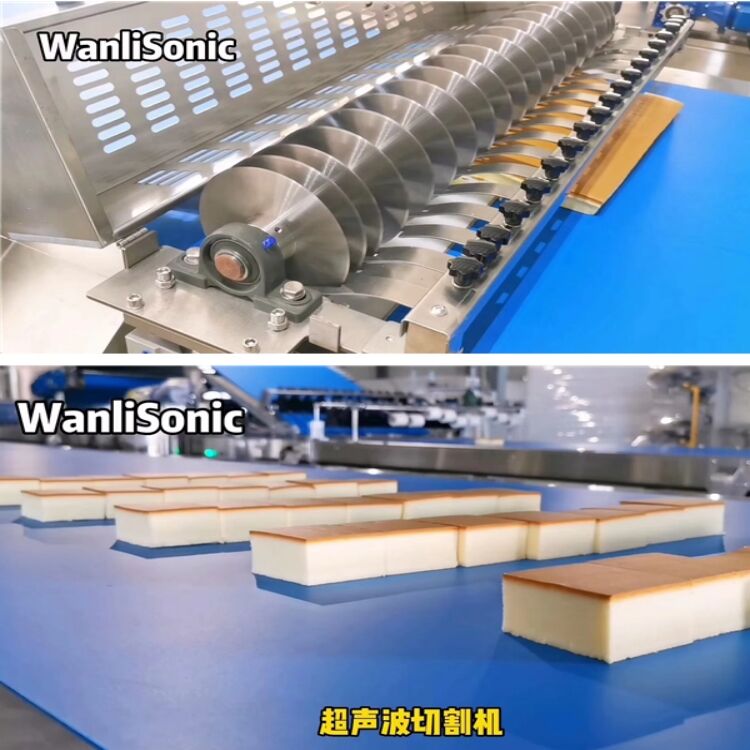

| Cutting Mode & Cutting Example |

|

| Features | Machine Dimensions (L xWxH) |

|

•The whole machine touch screen, photoelectric control, computer storage data, simple operation, high degree of automation. •Adopting international famous electrical components, stable and reliable performance. •Modular design of the machine set, various matching methods. •Baked Products with meticulous and uniform organization and good taste. • Product specifications, adjustable length and size. • This machine can make cakes without molds, the size of the cake specifications by the speed of the ultrasonic cutter. • The cake depositor machine has a special batter design, the batter does not drag, the position of the falling plate is precise, and the amount of batter is accurately controlled. • We are experienced in supporting production line, and we can customize the most suitable production line for customers according to their requirements and actual situation. • The most advanced technology is used to complete the production of traditional gourmet craft. • Cake,Dairy Products, Dough, Sushi, Pastry, Candy |

|

Product Description

Name |

Model |

Quantity |

Remark |

Picture |

|

Baking area furnace body, Aichi Tunnel oven technology to persuade the introduction of one of Japan's best cake tunnel furnace (with opening door cleaning system) |

|

34M |

Baking Oven Area:24M,Oven Head:7M,Oven Tail:3M. |

|

|

7M tension hub (including bracket) |

|

1 set |

|

|

3M tension hub (including bracket) |

|

1 set |

|

|

|

Motor screw deviation rectifying device |

|

1 set |

|

|

|

Oiling and homogenizing device |

|

1 set |

|

|

|

Double copper brush cleaning device (including scraper) |

|

1 set |

|

|

|

|

|

|

|

|

Cake coater |

1000 Model |

1 set |

Apply cake paste |

|

|

Edge guard Equipment |

|

1 set |

Steel band edge to prevent the flow of slurry out of the steel band |

|

|

Aerator Machine |

500Model |

1 set |

Standard configuration: Hair * 1, mixing tank * 1, storage tank * 1, screw pump * 1, rotor pump * 1, cleaning pump * 1, two sets of filters * 1,5p ice water machine * 1, electric control of mixing * 1, this device for light oil automatic inflation hair, the lowest value of specific gravity allowed in the formula structure (0.5) . |

|

|

Decorator Machine |

1000Model |

2 sets |

Salad Bar, can be spread sauce |

|

|

Spread Meat Floss Machine |

1000Model |

1 set |

Spread Meat Floss |

|

|

Spread Coconut Machine |

1000Model |

1 set |

Spread Coconut |

|

|

Out of the buffer mesh belt |

1200Model |

3M |

The whole line is made of 304 stainless steel plate, the frame is 45 * 75 * 2.0 square tube, the 5-minute pitch is 6mm 304 straight rod stainless steel with carbon steel chain, the motor is made of rain-field reducer |

|

|

Cooling mesh belt |

1200Model |

8M |

The whole line is made of 304 stainless steel plate, the frame is 45 * 75 * 2.0 square tube, the 5-minute pitch is 6mm 304 straight rod stainless steel with carbon steel chain, the motor is made of rain-field reducer |

|

|

Deviationcorrecting conveyorbelt |

1200M |

1 set |

Automatic induction control of cake transportation trimming size |

|

|

Hobber Slicer |

1200Model |

1 set |

Strip (size of strip to be confirmed by customer) |

|

|

PU conveyor |

1200Model |

7.5M |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Productionofacomplete setofformingturning device |

1200M |

1set |

The main parts are up-slope turning, down-slope turning, finishing, correct, Lane, the main material for 304 stainless steel processing and Pom |

|

|

Creammachine |

|

1set |

The cake was filled with cream |

|

|

Ultrasoniccutter |

1000Model |

1set |

The blade is made of pure titanium alloy 300 * 128. The transducer and automatic frequency-tracing power supply are designed by our patent. The aluminum and |

|

|

|

|

stainless steel parts are processed |

|

|

Food Curved Conveyor Machine |

180 Degree |

2sets |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

PU Conveyor |

1200Model |

21M |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Food Curved PU Conveyor |

1200M |

1set |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Conveyor belt after sealing |

1200Model |

18M |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Conveyor belt after sealing |

1200Model |

4.5M |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Conveyor belt after sealing |

1200Model |

8.3M |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Conveyor belt after sealing |

1200Model |

7M |

The whole line adopts 304 stainless steel sheet metal processing frame 45 * 75 * 2.0 square tubes, with Casley blue antibacterial PU belt, spindle welding drum coating treatment, front and back for aluminum plate blade, drive roller stainless steel tube processing, motor with five-horse reducer |

|

|

Sealing machine |

|

8sets |

|

|

|

Package Machine |

ZS180double blade |

1-3 |

Sinking Type 1 tow 3 packing machine packing |

|