Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

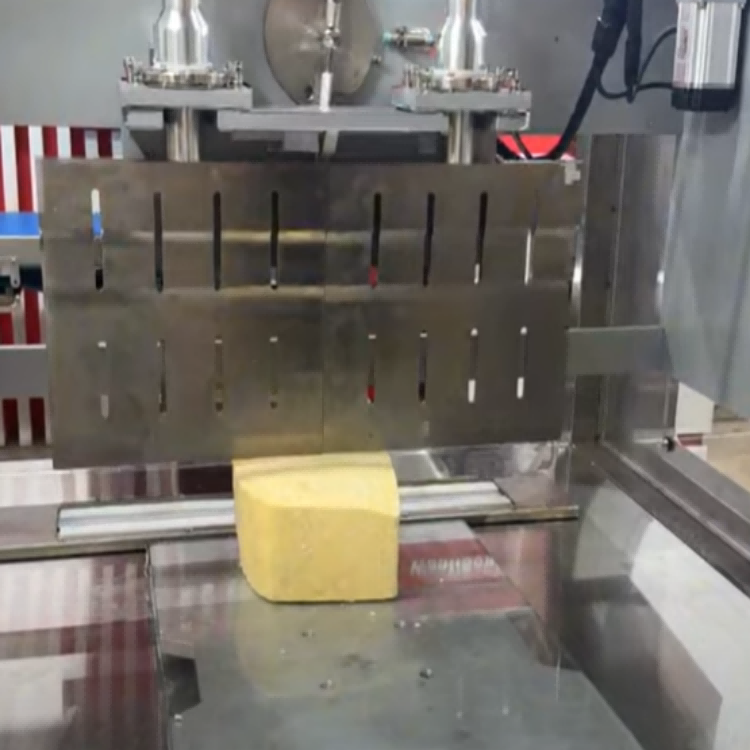

Wanlisp205 Ultrasonic Block Cheese Cutting Machine is a single-stage cutter designed for block cheese and butter portioning. It is multifunctional ultrasonic cutting machine for Cheese Cutting, 4-axis servo motor control system, the size can meet the requirements of various sizes. As an independent working machine, it can’t be connected with production line.

★Average speed: 30-40 cuts per minute

★Touch screen with user-friendly interface

★Reliable and durable ultrasonic machine

★Increased quality and labor saving enhance capacity

★Improved portion quality and consistency

Product Details Display

|

|

| Cutting Mode & Cutting Example |

|

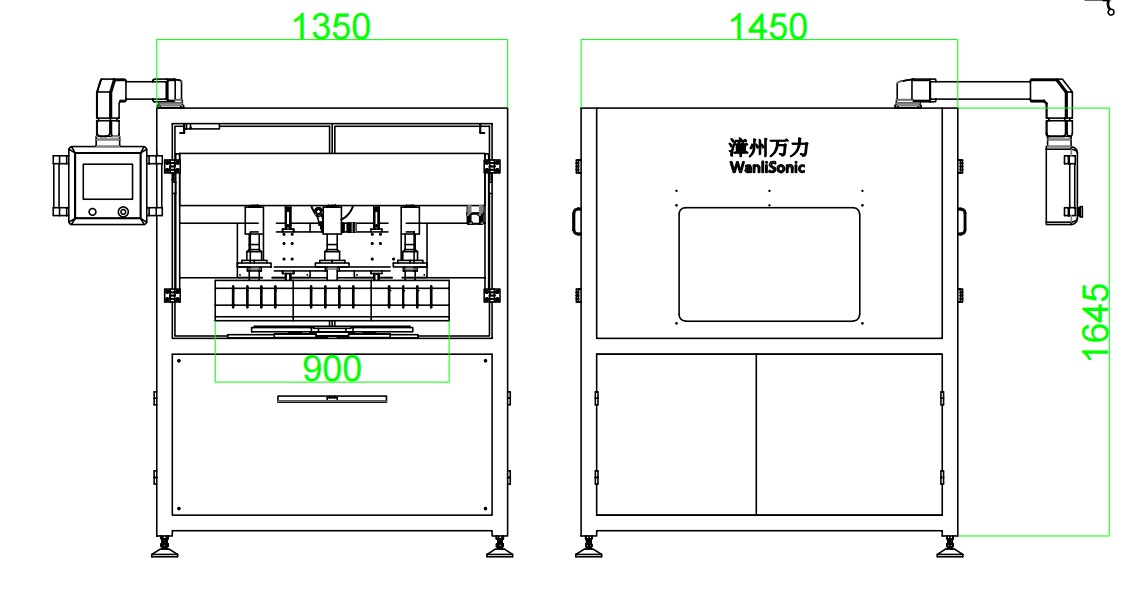

| Features | Machine Dimensions (L xWxH) |

|

• Fully Stainless steel construction & food grade plastics •Cheese |

|

Product Description

Model |

Wanlisp205(double wave)

|

Dimensions |

L1270*W910*H1800mm(Based on final drawings) |

Weight |

Net Wt. 320KGS, Gross Wt.420KGS |

Voltage |

220V |

Rated power |

4000W |

Frequency |

50Hz-60Hz |

Cutting speed |

35-60cuts/minute |

Number of blades |

2 double wave (optional) |

Blade materials |

Titanium Alloy |

Blade size |

300mm/pc(optional) |

Cut type |

Square, rectangular, round cake slice |

Maximum cutting size |

600mmx400mm,food cutting height up to 150mm |

Material of machine frame |

Stainless Steel |

Self cleaning |

Yes |

Safety protection system |

Security door, open safeguard, blade stop cutting. frequency ultrasonic scan and fault indicator lamp |

Control System |

Four-axis Control System |

Cutting knife control system |

Servo motor |

Machine mobility |

Casters |

Components

No. |

Name of Component |

Brand |

Introduction |

Picture |

1 |

Ultrasonic Blade |

Wanlisonic |

Made of Titanium Alloy material, The mechanical strength is better than that of steel, the acoustic transmission is good, the sound frequency is not depleted in its internal transmission, and it has strong acid-base corrosion ability, |

|

|

2

|

Ultrasonic Generator

|

Wanlisonic |

The advantages of original ultrasonic generator include automatic frequency lock function, automatic frequency tracking,low coefficient of temperature change, and there will be 7*24 hours of aging test before delivery.

|

|

3 |

Thicken and Bigger Cutting Machine Framework |

Wanlisonic |

Stainless steel, easy to clean, made with thicken china standard material, made by Anshan Iron and Steel Company |

|

4 |

Energy Transducer |

Wanlisonic |

Electric energy is converted to kinetic energy, to make the blade cut the products |

|

5 |

Touch Screen |

Wecon/Delta |

Intelligence control, for the operation and monitor |

|

6 |

PLC Control System |

Wecon/Delta |

Anti-error operation, safety testing, alarm indication |

|

7 |

Reley |

OMRON |

Touch switch |

|

8 |

Sensor |

Leuze |

For Testing whether have the products under the blade |

|

9 |

Frequency Inverter |

SANJING or Delta |

Driving the conveyor to work |

|

10 |

Servo Motor |

Dorna |

Driving the blade to work |

|

11 |

Stepmotor |

Dorna |

Driving the blade to work |

|