Contact Info

Unit 1011, Pingning Industrial, Longhai District, Zhangzhou City, Fujian Province

New York.

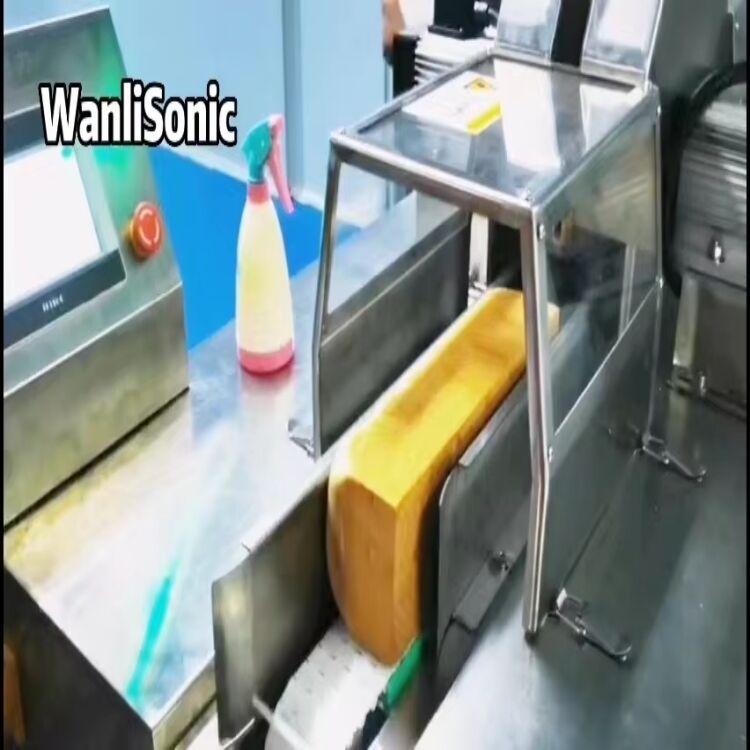

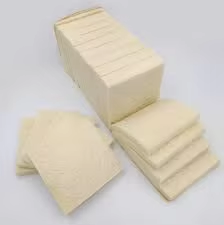

Wanlisonic-800K Automatic Toast Peeling Machine is a new model specially designed for Toast products. By using the blade chain, the skin can be easily and quickly peeled off in a stable condition. And yet the machine is adjustable to the peeling thickness as requested. It is safety-oriented, and it enables the workers to operate the machine easily and safely.This machine can remove the skin on all sides of toast. Smooth surface, fast speed, large output.It is suitable for industrialized toast bread production line, greatly improving work efficiency.

★Average speed: 25-35pieces/minute

★Touch screen with user-friendly interface

★Four-axis Control System

★Increased quality and labor saving enhance capacity

★Improved portion quality and consistency

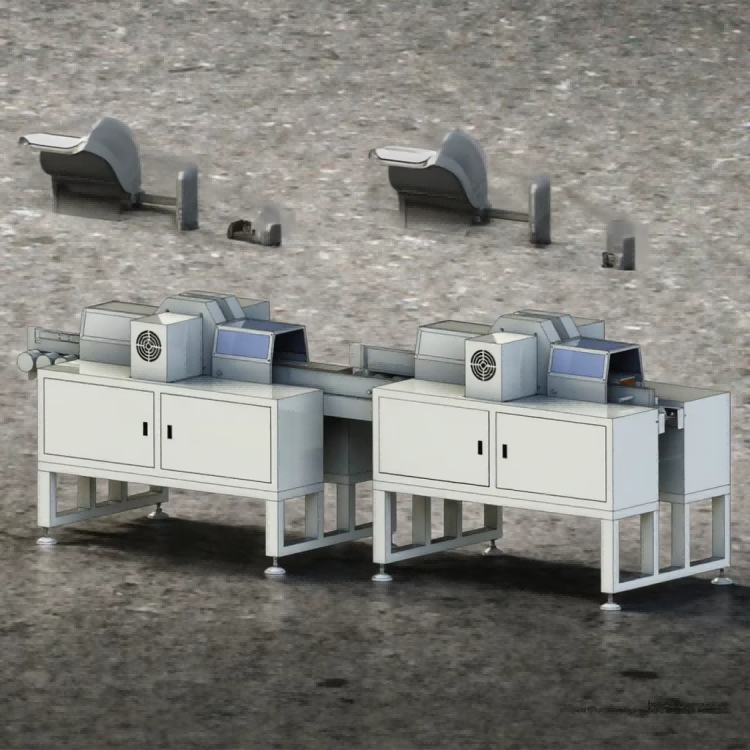

Product Details Display

|

|

| Cutting Mode & Cutting Example |

|

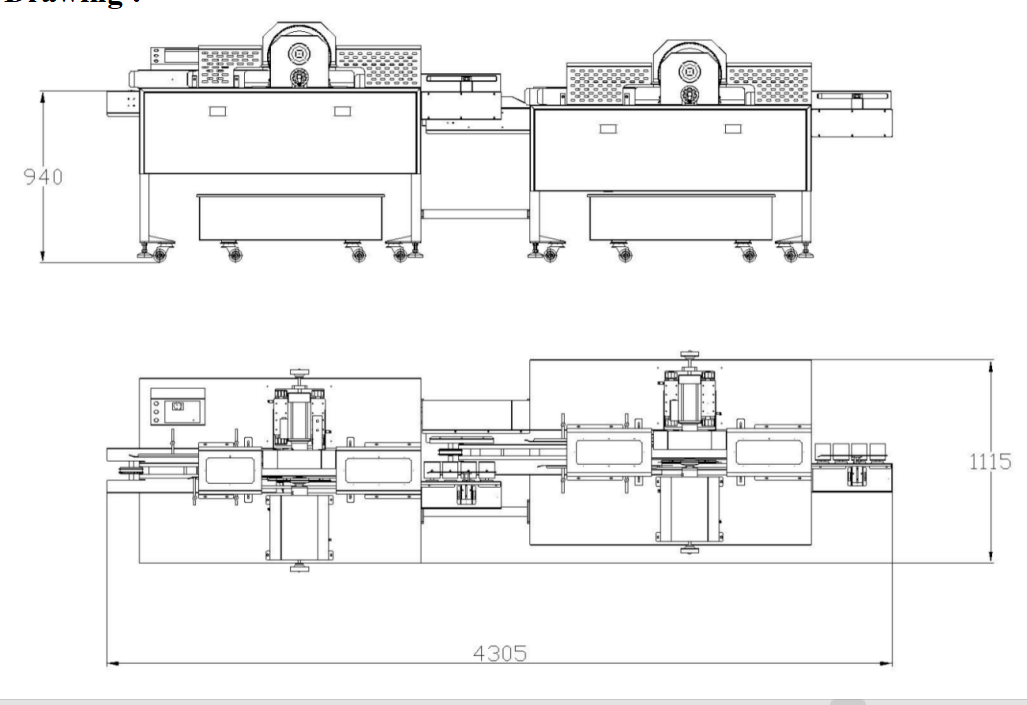

| Features | Machine Dimensions (L xWxH) |

|

• Stainless steel material • Patented slice design • Movable wheels and bolt-on frame • Adjustable peeling speed • Automatic toast flipping system • Cake,Dairy Products, Dough, Sushi, Pastry, Candy |

|

Product Description

Model |

Wanlisonic-800K |

Dimensions |

L1115*W4350*H1500mm(based on final drawings) |

Weight |

Net Wt. 280KGS, Gross Wt.300KGS |

Voltage |

220V |

Rated power |

2000W |

Frequency |

50Hz-60Hz |

Cut type |

Toast Peeling |

Material of machine frame |

Stainless Steel |

Automatic belt convey |

Yes |

Convey speed |

0-3000mm |

Control System |

Four-axis Control System |

Cutting knife control system |

Servo motor |

Certification |

CE |

|

Peeling speed

|

25-35pieces/minute |

Components

No. |

Name of Component |

Brand |

Introduction |

Picture |

1 |

Thicken and Bigger Cutting Machine Framework |

Wanlisonic |

Stainless steel, easy to clean, made with thicken china standard material, made by Anshan Iron and Steel Company |

|

2 |

Touch Screen |

Wecon |

Intelligence control, for the operation and monitor

|

|

3 |

PLC Control System |

Wecon |

Anti-error operation, safety testing, alarm indication |

|

4 |

Reley |

OMRON |

Touch switch |

|

5 |

Sensor |

Leuze |

For Testing whether have the products under the blade |

|

6 |

Frequency Inverter |

SANJING or Delta |

Driving the conveyor to work |

|

7 |

Servo Motor |

Dorna |

Driving the blade to work |

|

8 |

Stepmotor |

Dorna |

Driving the blade to work |

|